Calibration & Measurement Services

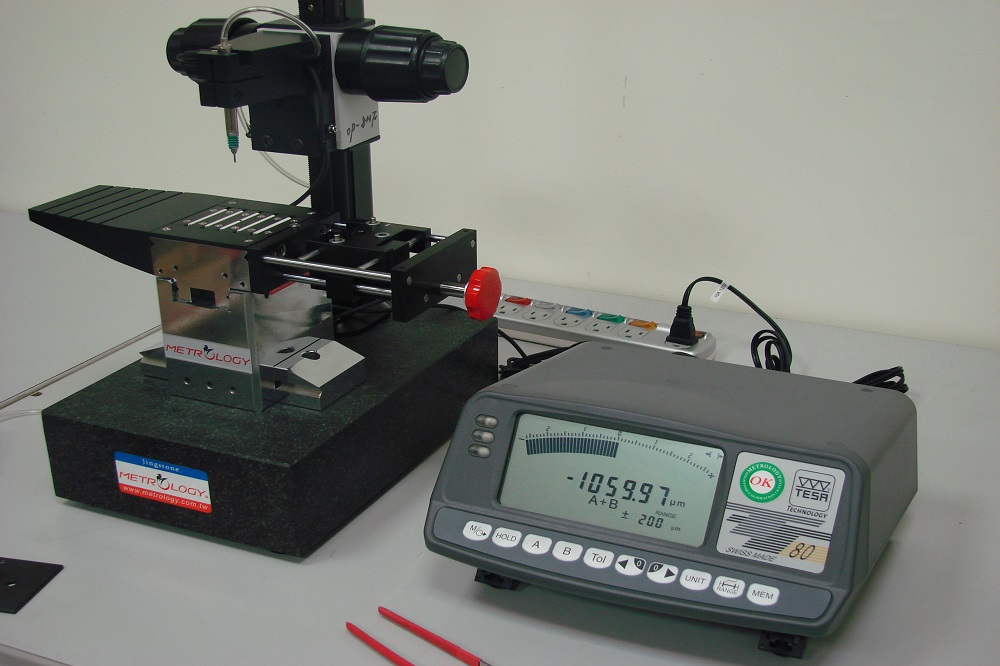

1 Calibration Lab

In our calibration Lab we provide accurate calibration services for wide range of Instruments, some of the calibration services we offer:

- Pressure Measurement

- Temperature Measurement

- Electrical Measurement

- Torque and Force Measurement

- Mass / Volume

- Gas Detection System

- Safety Related Measurement

Pressure Measurement

DELTA provides Pressure Calibration for:

- •Pressure Gauges

- •Relief Valves

- •Pressure Switches

- •Pressure Transmitters

- •Pressure Control Valves

- •Pressure Regulators

- •Pressure Test Manifolds

- •Chart Recorders & Reference Recorders

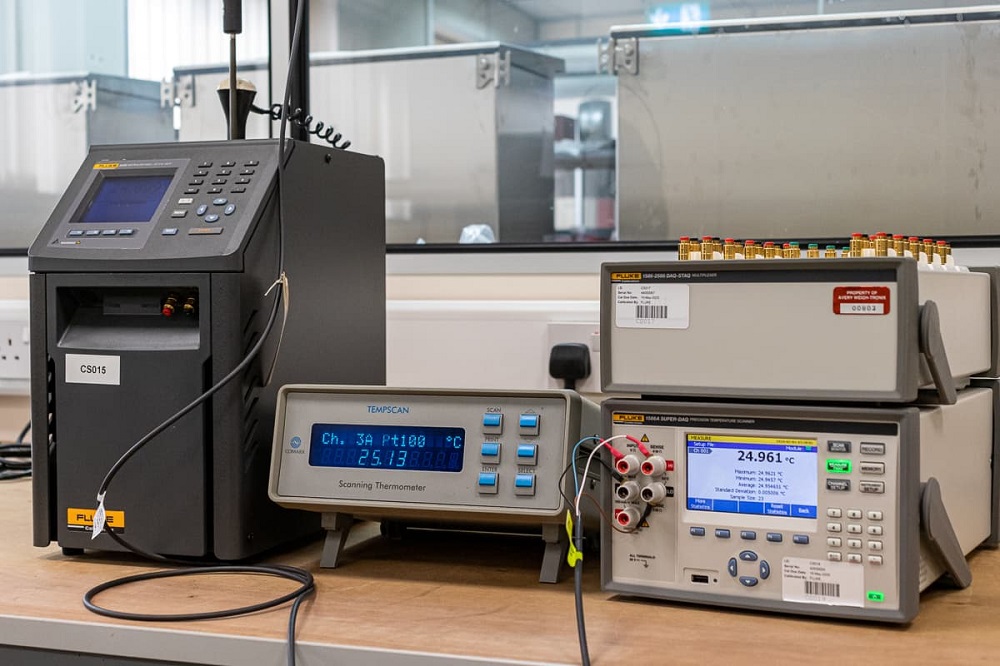

Temperature Measurement

DELTA provides Temperature Measurement for:

- Temperature Gauges

- Switches

- Control Valves

- Transmitters

- RTDs

- Thermocouples

- Ovens & Furnaces

- Welding Rod Ovens IR Thermometers

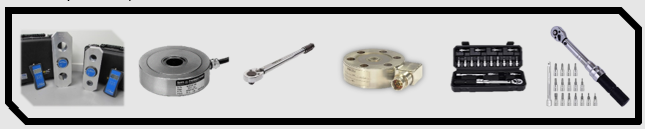

Torque and Force Measurement

DELTA provides Torque and Force measurement for:

- •Torque Wrenches

- Loadcell (Tensile & Compression)

Mass / Volume Measurement

DELTA Also provides Mass/Volume measurement for:

- Dead Weights

- Weighing Balances

Gas Detection System

DELTA provides Gas Detection System Measurement for:

- •H2S Gas Detectors

- •Multi-gas Detectors

- •SO2 Gas Detectors

- •Fire Detectors (UV/IR)

- •Flammable Gas Detectors

- •Line of Sight Gas Detectors

Safety Related Measurement

DELTA provides safety related equipment measurement for:

- SCBA Testing & Inspection: Refilling, Hydrotest and Maintenance of Self-contained Breathing Apparatus(SCBA) & Emergency Escape Breathing Apparatus(EEBA).

- Fire extinguishers: Testing and Refilling of DCP, CO2, Foam

2 FIRE & GAS CALEBRATION LAB

In our Fire & Gas calibration Lab, we prioritize Safety and Precision. Our services include:

- •Single / Multi Portable Gas Detectors: Calibration for accurate Detection and Safety (BW Technologies Honeywell, MSA, Drager, Industrial Scientific)

- •Fixed Gas Detection Systems (H2S/LEL 8 Channels Gas Detection System (Detcon, MSA, Industrial Scientific, General Monitors): Calibration and installation for comprehensive gas monitoring.

- •Area Gas Monitors (Industrial Scientific, Drager, MSA)

3 PRESSURE TEST FACILITY

Our Pressure Test Facility is equipped with cutting-edge technology to ensure rigorous testing and validation of High-Pressure Systems. The facility features:

- •Chart recorder: capable of recording pressures up to 30,000 PSI for precise and detailed monitoring.

- •Pressure Test Pump: a Haskell-manufactured pump that handles pressures up to 26,000 psi, designed for high-performance testing.

We conduct comprehensive tests on a variety of equipment, including:

- •Riser lines: ensuring structural integrity and

- Performance under pressure.

- •Chock/kill lines: validating safety and efficiency in

- Critical systems.

- •Booster/conduit lines: testing for reliability in fluid

- Transfer operations.

- •Coflex hoses: assessing durability and pressure tolerance.

- •Manifolds: verifying functionality and strength.

- •X-trees: ensuring safe and efficient operation.

- •Heat exchangers: testing for performance under high pressure.

- •Heaters: validating pressure handling and operational safety.

- •Piping: comprehensive pressure tests for piping systems to ensure reliability.

4 FLOW LINE TEST FACILITY

Our Flow Line Test Facility is designed to handle high-capacity and high-pressure flow line testing with advanced equipment. We offer:

- •High filling Pump: with a filling rate of 1,000 L/min, this pump ensures rapid and efficient fluid handling.

- •High Pressure Pump (6,000 psi): designed for precise testing with a filling rate of 20 l/min, ideal for high-pressure applications.

- •High Pressure Pump (4,000 psi): offering a filling rate of 10 l/min, perfect for a variety of pressure testing scenarios.

This facility supports us thorough testing and verification of flow lines, ensuring optimal performance and reliability in your operations.